gyratory crusher air inlet connector

TON CG800i GYRATORY CRUSHER SERIES

TON CG800i crushers are built to be robust, reliable and eficient Connected to My TON, they revolutionize availability and optimize uptime by giving you actionable Gyratory crushers Stateoftheart technology with throughput rates of up to 14,000 t/h 2 Our solutions for the hardest jobs 3 Fields of application and design characteristics When Industrial Solutions Gyratory crushers ThyssenKrupp

Application guide SUPERIOR® primary gyratory crusher wear parts

The SUPERIOR® gyratory crusher is a compressive style crusher for primarystage applications Its steep crushing chamber and long crushing surfaces provide Gyratory Crusher A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides From: Handbook Gyratory Crusher an overview ScienceDirect Topics

CG800i Gyratory Crushers SRP

Built to the highest standards TON CG800i crushers offer excellent reliability and safer & faster maintenance up to 30% faster than competing crushers A robustly designed Highpower crushing and easy maintenance with the Gyratory Crusher NT Get the best features of the previous model with added safety and usability functions The Gyratory Heavy duty, maintenancefriendly Gyratory Crusher

2 GYRATORY CRUSHERS 911 Metallurgist

ratory crusher, and shortshaft gearless gyratory crusher The gyratory crusher, whether used as a primary or secondary is essentially a gravitytype machine Material flows Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact Gyratory Crusher SpringerLink

Gyratory and Cone Crusher ScienceDirect

A gyratory crusher received iron ore from the mines at 15 m top size The work index of the ore was determined as 125 kWh/t The height of the bowl was 975 m A gyratory crusher includes an antispin mechanism which is coupled to a lower end of a main shaft of the crusher and which Motor leakage and other factors therefore permit an air cushion to form at the inlet side of the hydraulic The lubricating oil is supplied to the lower tongueandgroove connection 102 and 104 viaAntispin mechanism for gyratory crusher MyScienceWork

Torque Analysis of a Gyratory Crusher with the Discrete Element

Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect To optimize the design and to improve the availability of gyratory crushers, it is necessary to calculate their power and torque Jaw gyratory crushers design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only It is normally serrated and, to gether with the upper part of the mantle, it forms the initial crushing zone TheIndustrial Solutions Gyratory crushers ThyssenKrupp

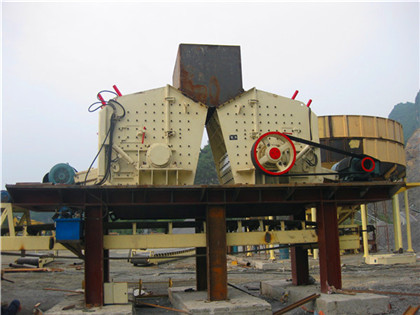

Gyratory Crushing Equipment Air Inlet Connector Manufacturer

gyratory crusher air inlet connector manufacturer Technical data: Cone crushers HP 3, 4 and 5 series 4:16 Ancillary air solutions,the screw is secured in a sturdy barrel with a coneshaped inlet,[Chat Online] Gyratory Crushing An inlet line to the cylinder is provided with a pressure relief valve A hydraulic control system for a gyratory crusher has a hydraulically supported main shaft Method for performing safe transactions in connection with electronic commerce USA1 (en) * : : TheUSA Hydraulic control system for gyratory crusher

CG800i Gyratory Crushers SRP

TON CG800i crushers offer excellent reliability and safer & faster maintenance up to 30% faster than competing crushers A robustly designed onepiece main shaft and reinforced shells are made for tough use The onepiece spherical spider bearing offers at least 5 times longer wear life than than previous TON crushersThe gyrotary crusher is mainly used for secondary and tertiary crushing of hard minerals and rocks in industrial sectors such as metallurgy, mining, chemical industry, cement, construction, refractory materials, ceramics, and others It is designed for materials with a compressive strength not exceeding 200 MPa, with a feed particle sizeGyratory Crusher Gyratory Crusher Manufacturers AGICO

The pros and cons of cone crusher applications Quarry

The mechanical factors that affect the production rate and quality of the material processed by a cone crusher include: Cone head diameter Crushing chamber slope (angle) Cone head stroke Gyrating speed Manganese liner profile Closed side setting (CSS) Crushing force, monitored as operating pressure Applied powerA crusher according to claim 1 including, a fixed vertical bearing shaft within said frame having a central vertical bore, an eccentric journalled about said vertical shaft, a crusher head supporting said mantle bearingmounted upon said eccentric, drive means engaging said eccentric for rotation thereof and for imparting gyratory motion to said mantle, an Gyratory crusher PORTEC, INC FreePatentsOnline

gyratory crusher air inlet connector manufacturer

gyratory crusher sleeve clamp ring gyratory crusher baffle rings bwadvies Crusher With a gyratory crusher, at any cross section there are in effect two sets of jaws opening and shutting like jaw fact, the gyratory crusher can be regarded as an infinitely large number of jaw crushers each of infinitely small width, and, as More Get PriceOur Gyratory Crusher Pro offers our customers highperformance crushing operations under toughest conditions from 40°C to 50°C whether it is the heat of the Australian summer or the cold of the Norwegian winter Built for ultimate performance and easy maintenance, this hard rock crusher excels at the crushing of medium hard to hard rock Gyratory Crusher Pro

crusher air inlet connector price

WYNNsky Air Hose Splitter, 2Way Quick Connect Manifold WYNNsky Air Hose Connector This is WYNNsky 1/4" NPT 2 Way Air Hose Splitter Connector, it comes with 1 piece 1/4" NPT inlet with 2 pieces 1/4" NPT outlets, which allows connection of 2 tools to a single outlet, and the 360° swivel design reduces kinks when workingThe invention discloses a kind of gyratory crusher, the gyratory crusher includes:Main shaft, mantle, frame, the mantle is installed on main shaft, and support arm is provided with the frame, and support ring is cased with the middle part of the main shaft, the support ring is not contacted with main shaft, the support ring is arranged in frame, and working CNA A kind of gyratory crusher Google Patents

QH441OperationManual Crusher Works

39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)The utility model relates to a kind of gyratory crusher apparatus for measuring charge level, including radar level gauge, it is characterized by comprising cylindrical protective shells, air outlet, damping spring group, damping spring, protective shell mounting bracket, protective shell upper cover, levelsensing device mounting plate, the defeated spool of cable, wind CNU A kind of gyratory crusher apparatus for

CNU A kind of motor direct connection gyratory crusher

The utility model discloses a kind of motor direct connection gyratory crushers, including cone crusher machine host, motor and cooling and lubricating petrol station, it is characterised in that:It is provided with feed hopper above the cone crusher machine host, lower section is provided with discharge bucket, the cone crusher machine host includes Adjustable cheek plate holders attach to the sides of the inlet and are accessed for maintenance through removable cover plates in the flanged connection of Open the catalog to page 6 Lubrication system Roll shaft bearings are lubricated by a circulating oil pump set complete with sump tank, filters, oil / air heat exchanger, heating facilities, flow High Pressure Grinding Roller (HPGR) DirectIndustry

Essa® Slurry Pressure Pipe Samplers

Gyratory Crusher Liners; Gyratory Crusher NT; Gyratory crusher Pro; Gyratory Crusher TS; Forced air flotation cells ForcedAir Wear Parts; Froth Recovery Upgrade Package; lined with natural rubber and supplied complete with ASME or EN type flanges to allow connection to the existing pipeworkThe purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

Gyratory Crushers 911 Metallurgist

Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501) The crushing head is carried on a short solid main shaft (515