design of dedusting baghouse filter cement plant

Cement Baghouse Filters for Dust & Emissions Control

Though each of our standard filter bags is proven to capture up to 9999% of emissions, we have a new product especially effective at helping cement plants PDF On Apr 1, 2016, Akshey Bhargava and others published Design of Bag Filter for the Control of Dust Emissions for a Cement Plant Find, Design of Bag Filter for the Control of Dust Emissions

Designing and Sizing Baghouse Dust Collection Systems

SECTION 1 The Four Key Baghouse System Design Variables For a dust collection system to function ade quately engineers must design and operate the This project helps to understand as a design guide which provides information that will help to achieve optimum performance and (PDF) Design analysis of Dust collection system

Improvement of cement plant dust emission by bag

The contribution of leakage in a baghouse filter (defined as a short circuit between the upstream and downstream sides of the filter) to the emission of fine particles is quantified in4 Filter bag vs pleated bag In terms of longevity and effectivity of your filters, it also depends on the type of filter you are using There have been several cases where replacing filter bags with pleated bags made a Cement plant maintenance: 6 tips to reduce baghouse

Design of Bag Filter for the Control of Dust Emissions for a

The design of Bag Filter in the present paper would demonstrate efficiency to the extent of 998 percent and as such would be able to meet the prescribed emission standards The main purpose of this study is to analyse the best design for baghouse filter to filtrate the coal of Portland cement plant The baghouse filter will be designed to OPTIMIZING THE PERFORMANCE OF FILTER BAGHOUSES AT

New Pleated Filters for Cement Kiln Baghouses and Other High

This paper will introduce you to a new hightemperature pleated filter design In addition, this new 500°F (260°C) rated pleated filter design is shown to For a dust collection system to function adequately engineers must design and operate the system to maintain the (4) key design parameters of airflow (measured in CFM), airflow velocity The Four Key Baghouse System Design Variables (Part

#impulse cleaning system bag filter Scheuch

National Cement kiln baghouse emc filter bag Siegener Verzinkerei Volumetric flow from 100 to over 3,000,000 Bm3/h can be achieved for dedusting, Customized solutions through processoriented design; Low plant differential pressure achieved through optimized dust and gas distribution and efficient separating;The basic function of a dust collector in the cement industry Cement production plants heavily rely on dust collectors that are represented in significant numbers In most cases, the core of the cement plant is the Cement plant maintenance: 6 tips to reduce

Fabric filters Andritz

The Fabric Filter (or baghouses or bag filters) uses a filter media to separate Particulate Matter (PM) from the flue gases The Particulate Matter are deposited at the surface of the fabric filter which may be made of different materials depending on the flue gas physical and chemical composition The dust is removed periodically when cleaning the bagsBaghouse Download as a PDF or view online for free 13Airto Cloth Ratio = Total volume of gas (or air) handled by the Bag filter [m3/min] / Total filtration area provided in the Bag Filter [m2] = [ m3/minm2 = m/min, => velocity unit; hence also called filtration velocity, and is actually the velocity at which the dust laden gases travel across Baghouse PPT SlideShare

How to select a dust collection system Plant Engineering

Baghouse dust collectors are best suited for use in industrial and manufacturing settings that require a high volume of material to be filtered on a regular basis Can be configured to withstand high temperatures In some cases, maximum operating temperatures are 250°F and up to 500°F Filters larger particlesContribute to chengxinjia/ development by creating an account on / dedusting of cement plantmd at main chengxinjia/

Cement Parker Hannifin Corporation

If you are responsible for daytoday baghouse or dust collection systems and equipment in your cement plant our training programs are designed for you We offer inperson seminars, complimentary Principles of Dust Collection webinar series, and we also visit plants and conduct onsite training that is tailored to your operation, your people, and your specific Filson has unique bag filters used in a cement plants that remove particulates, dust, and pollution generated by manufacturing and processing These products are using fabric or felt filter bags to extract dust from the air Bag material: polypropylene, polyester, acrylic, aramid, fiberglass, PPS, P84, PTFE Operating temperature: up to 260Bag Filter in Cement Plant Filson Filter

Baghouse Basics International Association of Operative Millers

Design Considerations • Interstitial Velocity Upward velocity of air/particulate between filters inside baghouse Measured in fpm (feet per minute) Determined by dividing airflow (cfm) by cross sectional area of filter housing less bag area Not to be confused with can velocity EXAMPLE: • 8,000cfm air required for dust control • Kice VR9610 Dedusting and separation systems are designed to remove or reduce dust, fine particles and other potential contaminants, or separate dissimilar materials This is done to improve the overall material quality and value, Dedusting Dedusting Equipment Kongskilde

Bag Filters in Cement Industry INFINITY FOR

Previous Post Next Post Contents Bag Filters in Cement Industry when you buy the package from here,you will get books + complete Courses + Manuals and Notes from very Reputable companies + confidential The supply consists of the new bag filter for kiln and raw mill exhaust gas dedusting at a rated capacity of 1090,000 Am³/h including the dismantling of the old electrostatic precipitator, the installation of the new filtration unit, connection of inlet and outlet ductworks, new fan and motor, compressed air supply system, commissioning and startup of the Dedusting Kiln and Raw Mill for Asia Cement CTP

Section 6 Particulate Matter Controls US Environmental

Another type of fabric filter developed in the 1970s and 1980s is the electrostatically enhanced filter Pilot plant baghouses employing this technology have shown substantially lower pressure drops than conventional filter designs Further, some cost analyses have shown that electrostatically enhanced baghouses could have lower lifetime costs than/ article dedusting system for cement grindingmd rwrr 325 KiB View; Log; Blame; View raw; 40cddf99 — mill2022 a month ago~mill2022/: article dedusting system for cement

Baghouses and Baghouse Filters Selection Guide: Types,

Baghouses, also called fabric dust collectors or fabric filters, are air pollution control devices designed to use fabric filter tubes, envelopes, or cartridges to capture or separate dust and other particulate matter (PM) Their applications range from small household workplaces to large industrial facilities such as coalfired power plants• Integrated cement plants including quarry operations and captive power plants (CPP) • Grinding and blending stations • Cement terminals • AFR preprocessing facilities The requirements of this Directive apply to active plants For mothballed and closed plants, the requirements do also apply, except for sections 22, 241, 242,Cement Environmental Directive Holcim

Baghouse

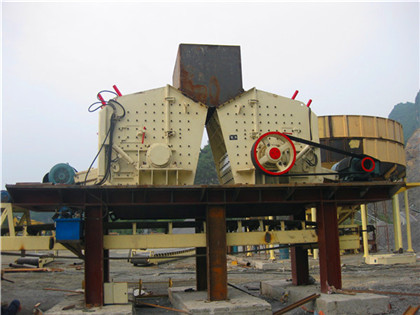

A baghouse, also known as a baghouse filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air Power plants, steel mills, pharmaceutical producers, food manufacturers, chemical producers and other industrial companies often use baghouses Pulse Jet Bag Filters for cement dedusting / baghouse dust collector $10,00000 $500,00000 Min Order Air Purification Filter for Cement Plant Pulse Jet Bag Filter $8,60000 Min Order: 1 set CN Supplier 13 yrs 00 /5 0 reviews Contact supplier Chat Now Sron Factory Design Fly ash Silo Cement Silo Storage Silo for CementBag Deduster For Cement Alibaba

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

gas side of the baghouse is one of the most important variables that must be considered in baghouse design Pressure drop through a baghouse is caused due to the air flow's resistance when air passes through the filtering bag and the filter cake Typically, the pressure drop is expressed in inches or centimeters of water