vibrating feeders at aggregate plant

Vibrating Feeders Transfer Crushed Stone at Aggregate

The vibrating feeders use a natural frequency drive system Each feeder is hung from a hopper and uses isolation springs between the The vibratory feeder is a forced vibrating system mostly used in industries to feed material from hoppers, bins, silos and storage piles to belt conveyors It is used to Dynamic analysis of vibratory feeder and their effect on

Syntron Material Handling Aggregates & Sand

The Syntron vibrating feeders are designed to increase bulk handling productivity with high feed rates MF — used for higher capacity requirements ranging from 600 to 4,000 tons Dynamic analysis of vibratory feeder A mathematical model of vibratory feeder is developed by considering forced vibration on a single degree of freedom Dynamic analysis of vibratory feeder and their effect on

Vibrating Feeders MEKA

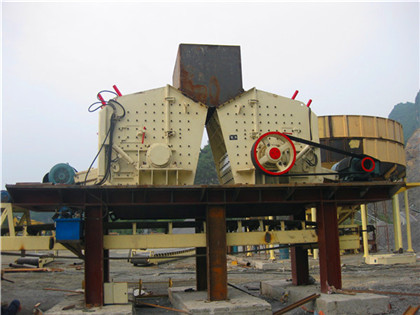

Vibrating feeders, known also as pan feeders, can be mounted on a fixed chassis or operated in suspended form, and are appropriate for use below bunkers, for the connecting of shafts in tunnels under open stocks, or In the world of aggregate crushing, the word “feeder” can apply to many different devices There are roller belt feeders, apron feeders, electromagnetic feeders, pan feeders and others This article Feeding the grizzly Quarry

Feeders Armstrong Equipment

® Simplicity Vibrating Grizzly Feeders are heavyduty pan feeders with grizzly sections added to the pan surface They perform both scalping and feeding in a single Vibrating Pan Feeders Vibrating Pan Feeders are generally used to feed primary crushers in aggregate, mining and recycling applications, but they can also be McLanahan Types of Feeders and Their Applications

McLanahan Types of Feeders and Their Applications

Grizzly bars on a Vibrating Grizzly Feeder allow fine material to pass through ahead of the crusher Vibrating Pan Feeders Vibrating Pan Feeders are generally used to feed primary crushers in aggregate, mining and recycling applications, but they can also be used to feed grizzly feeders for removing material ahead of a crusherThe 20″ rotor is equipped with 312 replaceable tungstentipped milling teeth that shred chunks of asphalt down to 1″ at a rate of 250 tons per hour The lump breaker eliminates offsite precrushing of asphalt materials to be Aggregate Feed Systems ADM Asphalt Drum Mixers

A FULL RANGE OF PROVEN FEEDERS

FEEDERS A FULL RANGE OF PROVEN FEEDERS Proper feeding ensures plant productivity and optimizing crushing and screening efficiency mekaglobal MEKA GLOBAL is reliable equipment manufacturer and supplier of spare parts and service to aggregate production, mining and associated crushing AGICO Cement provides crushing equipment, screening equipmen t, conveyor belt, sand making machine, and sand washing machine for processing all types of aggregate The capacity of the aggregate production line is up to 2000 TPH The finished size will be 05mm, 510 mm, 1020mm, 2040mm, 4060mm, and even largerAggregate Crushing Plant Aggregate Crushing Machine

Maintaining support springs in vibratory equipment Quarry

Poor motion in vibrating screens and feeders can occur for many reasons, but one is arguably the easiest to prevent and yet seems the least understood the adverse effect of support springs (the springs on which the machine sits) behaving differently from one side of the machine to the other The motion of the equipment will vary between Feeders move material forward at a given feed rate as part of the aggregate processing system Vibrating Grizzly Feeders combine the functions of a feeder and screen into one machine, which helps increase productivity and efficiency in the plant operation This type of feeder can be used in quarries, recycling, industrial processing,Feeders PECO Sales & Rental

Enhanced Plant Design for Aggregate Processing AggNet

Enhanced Plant Design for Aggregate Processing 15 October, 2012 Plant design, refurbishment or extension is dependent on the intended purposes and outcomes of the plant Steve Mellor explains why enhanced plant design can, The choice would normally be between a vibrating grizzly feeder,Vibrating feeder is commonly used to delivery raw materials to the crushers and vibrating screening equipment in the gravel aggregate processing plant And sort and remove the debris in it to facilitate the next processing procedure In the gravel aggregate processing line, the vibration feeder equipment is generally used to supply the stone 2Aggregate Processing Plant Design LZZG

Vibrating Feeders GRAU

Our Vibrating Feeders can be used under the primary feeding bins, before the secondary crushers with adjustable gates to control the flow and inside the tunnels for material extraction GRAU engineers can design different solutions to meet your unique applications in aggregate processing, mining and recycling industries® Simplicity Vibrating Grizzly Feeders are heavyduty pan feeders with grizzly sections added to the pan surface They perform both scalping and feeding in a single unit and are designed for impact loading and heavy burdens Standard grizzly feeder sizes range from 39" x 10' (990mm x 3048mm) to 86" x 24' (2184mm x 7315mm)Feeders Armstrong Equipment

Vibrating Feeder Design Stockpile & Reclaim General Kinematics

Vibratory feeders are basically applied to a control function to meter or control the flow of material from a hopper, bin, or stockpile, much the same as an orifice or valve control flow in a hydraulic system In a similar sense, feeders can be utilized as fixed rate, such as an orifice, or adjustable rate, as a valveOur hoppers and feeders will provide material handling solutions to meet your product requirements, including the handling of: quarry rock boulders; sand and gravel; recycle materials; or, any other freeflowing bulk materials This equipment is available in many configurations, including our standard preengineered models typically availableHoppers & Feeders Rock Systems

Feeders MEKA

MEKA Apron Feeders provide reliable means of controlling the feed rate to prevent surge loads to the Primary Crusher or other plant equipment An Apron Feeder is run at very low speeds and at a controlled feed rate as it with variable speed control is required Vibrating Grizzly Feeders have features similar to the Vibrating Feeder plus grizzly bars for separating fines from crusher feed This feeder increases crushing plant production and reduces crusher liner wear because fines are bypassed around the primary crusher Both feeders are available in widths frommineral processing handbook Permanent Court of Arbitration

Vibrating Feeders Grizzly Feeder Manufacturer from Tambaram

No 20/7, Kuttiyappan Street, Davidpuram Tambaram , Kanchipuram, Tamil Nadu, India Corporate Video Manufacturer of Vibrating Feeders Grizzly Feeder, Electromagnetic Vibrating Feeders, Electro Mechanical Vibrating Feeders and Tubular Vibrating Feeder offered by Magwell Industries, Tambaram, Tamil NaduThese feeders can also be totally enclosed and use a vibratory tube feeder design Drive options include electromagnetic or electromechanical (rotary electric) drives, as well as pneumatic vibrator drives View Product Line Ask a question or Get a Price Quote Use our Express Contact Form or call: (979) 2171480Large Vibratory Feeders Industrial Material Feeding Solutions

Vibrating Feeders MEKA

Just call +903123979133 and we will help you in any way we can You can also send an email to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information Use the Call Back option if you would like to be contacted by our sales team MEKA Vibrating Feeders are designed for highDeister Screens and Feeders A highcapacity, twodeck, 5′ x 12′ inclined drum mix asphalt plant scalping screen with reversible side discharge chutes, undersized chute, stationary deck selector/bypass chute and subbase A heavy duty, threedeck, 8′ x 20 inclined washing/rinsing screen with dual vibrating mechanisms and baked epoxyDeister Screens and Feeders Aggregates and Mining Today

Crushing & Screening Plant Design Factors 911 Metallurgist

Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or DOVE Vibrating Grizzly Feeders are designed for continuous and efficient classification, separation of the ore and aggregate for sizing, removing the unwanted and oversize materials and bypassing the smaller particles for the Crusher, or Trommel, and the processing plant, which results in maximizing the plant capacityvibrating feeders at aggregate plant