hematite iron ore beneficiation plants hematite iron ore

Introduction: Overview of the global iron ore industry

In many instances, China’s iron ore beneficiation plants are designed to recover more than just the iron minerals from the ore For example, the processing 11 Types of iron ore Iron ores can be classified in different ways The most important has to do with the iron content In many cases, ore with a total iron content of 60% to 63%, Beneficiation Plants and Pelletizing Plants for Utilizing

A Study on HighGrade Iron ore Beneficiation to Reduce

On average, one percent increase in iron content improves productivity by 2% and reduces coke consumption by 1% Therefore higher iron ore feed content to The beneficiation of a hematite ore fines with magnetization roasting and magnetic separation was proposed and studied • The magnetic properties of ore Beneficiation of an iron ore fines by magnetization

Iron ore quality a potential headwind to green

Among options to address this issue is a significant switch in iron ore mining focus from hematite towards magnetite Magnetite ores tend to have a much lower Fe content but are often suitable for Microwaveassisted magnetizing roasts were used to produce an iron ore product from lowgrade, goethitedominant, iron ore plant rejects Goethite was found to Beneficiation of lowgrade, goethiterich iron ore using

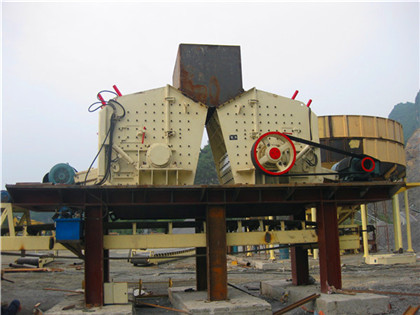

Arrium's Iron Baron Hematite Beneficiation Plant AusIMM

Since 2008, Arrium has been developing and commissioning a new lowgrade hematite ore benefication plant (or OBP) at its Iron Baron mine siteThe Iron Baron mine, which was Iron ore, the raw material for the steel industry, is critical for the sustainable development of the global economy (Yellishetty, Ranjith and Tharumarajah 2010) Global demand for iron and stee Beneficiation Strategies for Removal of Silica and Alumina from LowGrade HematiteGoethite Iron Ores: Mineral Processing and Beneficiation Strategies for Removal of Silica and Alumina from

4 Kinds of Hematite Ore Beneficiation Processes How To Choose

Among them, hematite, as a weak magnetic iron ore, has uneven particle size and high content of fine particles Hematite ore is an important iron ore resource in my country In the early 1960s, hematite ore was mainly processed by roastingmagnetic separation and singleflotation processes, and the production technical indicators were On average, one percent increase in iron content improves productivity by 2% and reduces coke consumption by 1% Therefore higher iron ore feed content to blast furnace is always preferred Indian hematite, though rich in iron content has a higher content of alumina and lower silica content Alumina to silica ratio is as high as 15–3%A Study on HighGrade Iron ore Beneficiation to Reduce

Mineral and Technological Features of Magnetite–Hematite Ores

content ranges from 5069 to 5188%; bivalent iron is present in small quantities—the FeO content in the samples ranges from 353 to 416% The content of magnetic iron is 1140–1267% Based on the obtained results by the investigation of the features of magnetite–hematite ores from the Mikhailovskoye deposit, a technological of the iron ore as well as iron and steel industry, and the way forward for meeting the set goals 2 INDIAN IRON ORE RESOURCES India is endowed with large resources of iron ore, which is estimated to be about 2852 billion tonnes of both hematite and magnetite ores Table 1 Iron Ore Resources as on 01042010 (In billion tonnes)(2) Ore ReservesCHALLENGES OF INDIAN IRON ORE INDUSTRY GEOLOGY,

(PDF) Flotation of Iron Ores: A Review ResearchGate

Overview of the beneficiation process used by the Yuanjiacun iron ore concentrator, utilizing anionic reverse flotation (based on Chen, Ge and Yu 2005; Mao, Huang and Zhao 2005) FiguresThe recovery of fine iron ore by magnetic separation will decrease with decreasing particle size because the magnetic susceptibility of magnetic particles decreases with a decrease in particle mass There is an example of an Australian ironore operation that introduced beneficiation of fine haematite, 100 µm, by using WHIMS2Maximizing the recovery of fine iron ore using magnetic

Iron Ore Processing, General SpringerLink

Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic Washing of iron ore fines and slime (10% and 25% w/v, slurry concentrations) with two types of surfaceactive agents (sodium humate (synthesized) and AD 200 (commercial)) at varying concentrations at pH 8 was conducted for ascertaining the efficacy of dispersants in beneficiating the lowgrade iron ores The beneficiation Upgradation of Iron Ore Fines and Slime by Selective Hindawi

Comminution and classification technologies of iron ore

Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) productsMethods to evaluate the liberation characteristics of an iron ore feed in a jigging plant have been given by Mukherjee et al (2008) Das et al (2007) studied the beneficiation of a lowgrade(PDF) Effective Beneficiation of Low Grade Iron Ore

Beneficiation of LowGrade Dilband Iron Ore by

This research is aimed at the upgradation of indigenous Pakistani iron ore, ie, Dilband iron ore (hematite), by utilizing common metallurgical processes First, the magnetic properties of the ore were The present study focuses on utilization of iron ore slimes without beneficiation by blending with highgrade fines for making iron ore pellets The pellets were prepared by adding slimes in different weight proportions (0, 10, 20, 30, 40, and 50%) with highgrade iron ore finesPelletization of hematite and synthesized magnetite concentrate from

New perspectives in iron ore flotation: Use of collector reagents

The flotation processes performed in the main iron ore beneficiation plants located in the Iron Quadrangle region (Brazil) consist of flotation of natural fine particles Utilization of humic acid as a depressant for hematite in the reverse flotation of iron ore Miner Eng, 20 (2007), pp 10031007, 101016/jmineng200703007Fig 3 Types of processing ores The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore The wet process consists of multistage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc, but the advantage is only partial Beneficiation of Iron Ores IspatGuru

Iron Ore Geoscience Australia

Download Iron (Fe) is a metallic element that constitutes 56% by weight of the Earth's crust and is the fourth most abundant element in the crust Iron ores are rocks from which metallic iron can be economically extracted The principal iron ores contain hematite (Fe 2 O 3) and magnetite (Fe 3 O 4 ) Hematite is an iron oxide mineralMonograph on Iron Ore; Indian Bureau of Mines: Nagpur, India, 1997 [Google Scholar] Raj, B Development of a Process flow sheet for Beneficiation of Indian Banded Hematite Quartz (BHQ) Iron Ore In Proceedings of the Iron Ore 2007 Conference Perth: AusIMM, Perth, Australia, 20–22 August 2007; pp 375–380 [Google Scholar]Minerals Free FullText Recovery of Hematite from Banded Hematite

Pelletization of synthesized magnetite concentrate obtained by

However, the impact of iron ore beneficiation and pelletization on the environment plays a vital role in terms of fossil fuel consumption, an increase in the carbon footprints, and generations of considerable airborn dust particles 411 Pelletization of hematite iron ore and process complicationsOverview Hematite is a kind of iron oxide ore, the main component is Fe2O3, it is dark red, the specific gravity is about 526, and it contains 70% Fe and 30% OHEMATITE BENEFICIATION PROCESS, HEMATITE BENEFICIATION EQUIPMENT

Developments in iron ore comminution and classification

Hematite and magnetite are the most prominent iron ores Most of the highgrade hematite iron ores (direct shipping ore (DSO)) are subjected to simple dry processes of beneficiation to meet size requirements This involves multistage crushing and screening to obtain lump (− 315 + 63 mm) and fines (approximately − 63 mm)