Key Parameters For Jaw Crusher Customer Case

TON JAW CRUSHER SERIES TON Mining and Rock

Our jaw crushers are of the singletoggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that offers smooth Optimisation results showed that the optimal design parameters were: 4006 mm thickness, 494 mm plate profile, and 99621 mm height An analysis using the Optimisation of the swinging jaw design for a single toggle jaw

Materials Free FullText Influence of Basalt Aggregate Crushing

The use of mineral aggregates is related to the increasing demand in construction, railway and road infrastructures However, mineral aggregates can appear to be of variable quality, directly affecting their suitability for respective earthwork applications Since the production of mineral aggregates should ensure the standardized, highquality In this study, TTTplot is used to analyze rate of failures of crusher and its components considering time between successive failures (TBFs) Since this is often not the case are indicative ofFailure rate analysis of Jaw Crusher: a case study

TECHNICAL SPECIFICATIONS TON QJ341+ JAW CRUSHER

JAW CRUSHER TECHNICAL SPECIFICATIONS QJ341+ DATA Crusher Type Single toggle C12 jaw crusher Feed opening 120 m x 750 mm / 47” x 29” Speed 264 283 rpm Adjustment type Hydraulic wedge CSS range 50 160 mm / 2” 6” QJ341+ DATA Power pack Engine CAT C93B Stage 5 / T4F 280 kW / 375 hp CAT C9 T3 261 kW / 350 hp13 The concept and data analysis technique This work analyzes failure rates of crusher and its components using LDA method, ML method and TTTplots The ML method needs application of software for solving mathematical equations The TTTplotting does not need structured data setFailure rate analysis of Jaw Crusher: a case study Sādhanā

Jaw Crusher an overview ScienceDirect Topics

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) This crusher can handle products with a Mohs hardness that is not necessarily less than 5 As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesThere are a sufficient number of works devoted to modeling crushing machines Nevertheless, the fact that there are a large number of working conditions, and the ongoing development of science and technology, require continuous improvement and specification of the models intended for crushing processes and those of the devices Mathematical Modeling and MultiCriteria Optimization of Design

A fundamental model of an industrialscale jaw crusher

Abstract In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al, 2015) Approaches to date have been mainly property specificFactorial design is used to determine failure rates using shape parameter, scale parameter and time failed data Failure rates of jaw crusher and its components are examined by 2 3 full factorial designs with two levels (high level and low level) and three variables High level is indicated as +1 and low level as −1Failure analysis of jaw crusher and its components using ANOVA

Calibration and Validation of a Cone Crusher Model with MDPI

This paper reports the calibration and validation of a cone crusher model using industrial data Usually, there are three calibration parameters in the condensed breakage function; by contrast, in this work, every entry of the lower triangular breakage function matrix is considered a calibration parameter The calibration problem A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the LN contact force model and modified Coulomb friction force model The correctness of the dynamic model is verified by MATLAB and Adams comparison simulation, and the Dynamics Analysis and Chaos Identification of Compound Pendulum Jaw

Failure analysis of jaw crusher and its components

In this case, the value of R 2 of jaw crusher is 9898 %, back toggle plate is 9887 %, chute liner plate is 9283 %, jaw plate is 9964 % and tie rod is 9312 % and isFor improving the performance parameters of jaw crusher modified design and modeling can be a possible solution Kinematic analysis and modeling can be used to estimate the design performance by considering different operating parameters like velocity, position and displacement of various links [ 12 ]Stone Crushers: A Technical Review on Significant Part of

Tutt Bryant debuts Jonsson products for heavyduty

Jonsson designs and manufactures some of the world’s most formidable heavyduty, trackmounted crushing and screening plants With crushing equipment in the 70180 tonne range, these are ideal C120 jaw crusher large concrete crusher parameters bandbportopinoit C120 is a reliable jaw crusher engineered especially for quarrying and mining applications Designed based on customer feedback and decades of experience at various customer sites C120 jaw crusher provides excellent productivity and low cost per ton regardless of Deepak Key Parameters For Jaw Crusher Customer Case

(PDF) Calibration and Validation of a Cone Crusher Model with

This paper reports the calibration and validation of a cone crusher model using industrial data Usually, there are three calibration parameters in the condensed breakage function; by contrast, inDownload scientific diagram Schematic description of the crushing plant, (1) primary crusher, (2) secondary crusher, (3) tertiary crushers, (4) final screens and (5) a switch for changing theSchematic description of the crushing plant, (1) primary crusher, (2

Optimisation of the swinging jaw design for a single toggle jaw crusher

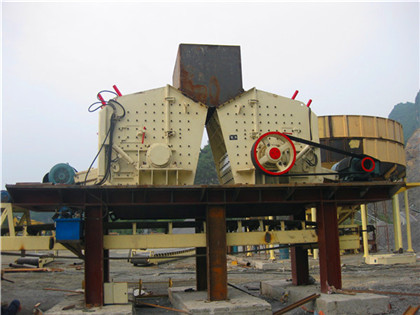

The plate dimensions of the unoptimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig 3The load and boundary conditions for the static structural analysis were as shown in Fig 4Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were Jaw crusher Crushing Equipment HuaHong Machinery Though the working environment is extremely harsh, the jaw crusher still can work very reliably this is a key element to ensure the productivity Technical parameters of Jaw crusher Model Max feeding size (mm) Adjusting range of discharge opening Read More; Jaw Crusher Workingkey parameters for jaw crusher

HP Series cone crushers High performance crushing

temperatures, RPM and other key parameters in your HP cone crusher The protection is activated in steps, starting from informative warnings and progressing to limiting the feed material coming into the crusher, and eventually shutting down the crusher to protect the crusher whenever needed Optional IC Series crusher automation11Figure 2 A double toggle jaw crusher Table 1 TBFs of the crusher and their components System/subsystem No of failures Time between failure (hours) Jaw crusher 40 250, 370, 380, 396, 273, 300Failure rate analysis of Jaw Crusher: a case study ResearchGate