gypsum processing innovative

Innovative gypsum processing at GIPS AD

Innovative gypsum processing at GIPS AD 21 May 2013 GIPS AD has been active in the gypsum and plaster market in Bulgaria for many years It sells not The intensive research activities on gypsum as a resource form the basis for improving the resourcesaving use of this raw material in future and offer the opportunity to safeguard Innovative research approaches to gypsum recycling

Development of a new process to produce gypsum products from

On federal and state level, a large number of research activities are underway to find short, medium and longterm innovative solutions to increase the availability of recycled The newly developed processing method is aimed at producing potassium sulphate as fertilizer with calcium sulphate as a byproduct Fig 2 shows a simplified flowchart of the intended process The new process entails various process steps: First, any existing nonrelevant minerals are to be removed from the crude saltDevelopment of a new process to produce gypsum products from

Gypsum processing plant Varlik Makina Sanayi İç ve

Varlık Makina is your most comprehensive solution partner for the processing of natural or synthetic gypsum Varlık Makina has over 40 years of knowhow, an efficient design capability and offices, and stateof Plaster, blocks and boards manufacturing industries utilize gypsum waste after processing and reducing the impurities to certain values as specified in Indian Standards IS: 126791989 [73, 78] Current utilization practices for marble waste and gypsum wastes (phosphogypsum/FGD gypsum) based on the literature reviewed in A review on calciumrich industrial wastes: a sustainable Springer

The path to a circular economy: a European collaborative project

Processing gypsum demolition waste By developing innovative techniques in pilot plants, the GtoG project aims to incorporate up to 30% secondary gypsum (recycled gypsum in the gypsum product coming from production, construction and demolition waste) in those pilot plantsIn 2020, around 45 000 t RC gypsum was produced from gypsum waste in Germany [3], which corresponds to less than 1 % of the FGD gypsum used in the gypsumprocessing industry So, probably, even a substantial increase in the quantities of recycled gypsum would not satisfactorily close the FGD gypsum gap, which necessitates a search for Innovative research approaches to gypsum recycling

Gypsum Ammermann

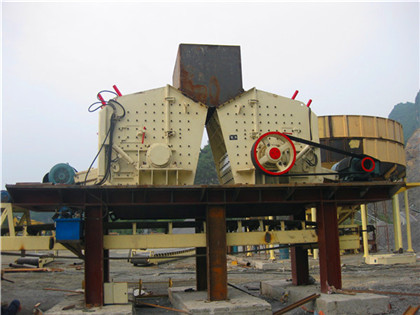

Gips AD gypsum processing plant, Bulgaria Standing as a true leader within the gypsum industry, Claudius Peters is able to engineer tailormade solutions that meet any desired product qualities and system performance requirements Stateoftheart technology to meet any calcining Claudius Peters continues to remain at the fore requirementGypsumbearing industrial waste is promising for use in the production of commercial goods in various economic sectors (for example, rareearth metals, gypsum binders, construction materials, and organomineral fertilizers) [1–5]Extensive research has confirmed that a comprehensive processing approach generating several products is Cyclone Design for Systems Processing GypsumBearing Waste

Gypsum a scarce raw material? Mineral Processing

One speciality is evaporite gypsum, which is formed during the evaporation of seawater for the production of salts In 2019, a total of around 435 Mta synthetic gypsum was produced worldwide (Fig 7) Of this quantity, 1368 Mta or 314 % were used in industry Of the 176 Mta FGD gypsum produced, 728 % were used worldwideThe British Gypsum Robertsbridge wallboard plant, part of the French building materials giant SaintGobain since 2005, is located near the village of Robertsbridge in rural East Sussex One of the largest employers in the local area, the site has been used for gypsum production for over 100 years, first as a plaster of Paris plant and then as a Articles on the gypsum industry from Global Gypsum

Innovative research approaches to gypsum recycling

In 2020, around 45 000 t RC gypsum was produced from gypsum waste in Germany [3], which corresponds to less than 1% of the FGD gypsum used in the gypsumprocessing industry So, probably, even a substantial increase in the quantities of recycled gypsum would not satisfactorily close the FGD gypsum gap, which necessitates a search for Paper 8 Innovative gypsum processing at Gips AD Koshava: Lars Roettger: Claudius Peters Paper 9 Thermoplastic innovation the future?: Neil Woolliscroft: Derco Paper 10 A safe and ergonomical method for handling and packaging plasterboards at high speed: Christian Fliss: Jürgens Maschinenbau GmbH & CoKG 2011Global Gypsum Knowledge Base, news, plants & more on the gypsum

About The Siam Gypsum Elephant Gypsum Thailand

About Elephant Gypsum Board The Siam Gypsum Industry (SCG), the leading innovative construction materials and chemicals company in Thailand and A Knauf Knauf Group continues to operate as a family business and is present in over 90 countries with over 80 raw materials processing plants and over 300 manufacturing plants on fiveGypsum (CaSO 4 2H 2 O) is an abundant and easily accessible mineral on the Earth’s surface and is extensively used as a source for building materialsThe production procedure has, fundamentally, not changed since prehistoric times and involves the heat treatment of gypsum rock at ~200 °C, inducing dehydration and recrystallization Advanced materials engineering in historical gypsum plaster

Influence of rice husk ash (RHA) with gypsum and ichu fibers in

According to the results of Fig 14 shows the mechanical strengths with the optimal molarity (12 Molar), optimal percentage of gypsum (20% gypsum), with the mixing processes A, B and C broken at 7, 14 and 28 days of curing, it was evidenced that the best treatment was the mixture A × 28 days of curing, reaching an average strength of 972 Table 11161 (cont) c Typical pollution control devices generally have a negligible effect on CO 2 emissions d Factors for these operations are in Sections 1119 and 132 e References 34,8,1112 Equation is for the emission rate upstream of any process cyclones and applies only to concurrent rotary ore dryers with flow rates of 75 cubic meters per 1116 Gypsum Manufacturing US EPA

Gypsum as a Construction Material A Review of Recent

When used precisely with the innovative materials gypsum can develop the ability against moisture penetration and stability towards impact Several research works have been done on the mechanical property and durability of gypsum under various circumstancesunderstanding of the gypsum wallboard process Our target is to simulate under labconditions the whole production process The lab screening results must be reliable and transferrable to the plant conditions A careful balance is considered to achieve both physical performance parameters as well as economic processing conditions, to get theBASF Solutions for Gypsum Wallboards Applications

Sustainability Free FullText Quantifying Environmental Burdens

This innovative gypsum calcination process provides no emission of CO 2, NO x, SO x, and combustion dust the processing of raw materials, and the processing of secondary material, including recycling processes, A2—transport to the manufacturer, and A3—productionGypsum Processing At Enviro Grind Ltd, we provide a solution that is tailored to your needs Gypsum Processing at Enviro Grind Statuary Regulations relating to the landfill disposal of Gypsum products including demolition plasterboard have enabled Enviro Grind to create innovative environmental solutions ahead of its competitorsGypsum Processing Enviro Grind Ltd

Factsheet on: What is Gypsum?

Gypsum is normally only screened to remove ‘fines’ (mainly mudstones), then crushed and finely ground Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker C Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, three