working of ball mill in paint ma nufacturing company

/ working of ball mill in paint ma nufacturing

Contribute to changjiangsx/ development by creating an account on 3512: Ball Mill This type of mills uses small balls that crashed with colloid particles, it has two types classified according to its Paints Industry: Raw materials & unit operations

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis The axiContribute to sili2023/ development by creating an account on / working of ball mill in paint nufacturing companymd at

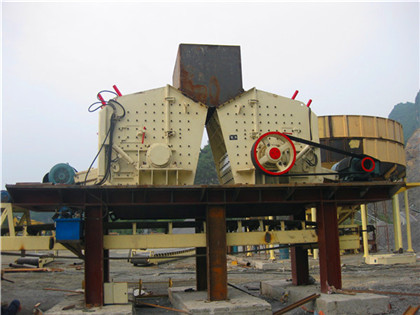

Ball Mill manufacturer, supplier, and exporter in Mumbai, India

Contact Us: +(91) to Get Latest Quotes for Ball Mill, Continuous Ball Mill from Raymer Engineering Working/ Operating Principle of Ball Mill Ball mill is also widely used in the manufacturing industries, such as paint manufacturing, enamels manufacturing, cement primers, Silicate, Fertilizer, Design and Analysis of Ball Mill For Paint Industries Mayur H Patel1 Mr Vishal A Pandya 2 1MEMachine Design pursuing2Asst Prof 12 BVM Engineering College, Total load = steady load + working load = 1455+ (025 1455) =1820 kg E Design Of Shaft For Rotating At Optimum Speed [11]:Design and Analysis of Ball Mill For Paint Industries IJSRD

India's Best Quality Ball Mills Manufacturer Bhagawati

Bhagawati Manufacture Ball Mill from 25 kg We are Manufacturing Batch type Ball mill with capacity from 25 kg to 60 Ton for Ceramic industries, Mining industries, Ceramic Ball MillsMineral Processing Ball mill machine working #ballmill #newstatus #newvideo #ytRaymer Engineering Corporation Bead Mill is widely used in industries like paint manufacturing, inks manufacturing, agrochemicals, pharmaceuticals, printing inks, cosmetics, etc Contact Us: + (91) to Get Latest Quotes for Bead Mill, Vertical Bead Mill, Horizontal Type Bead Mill, Bead Grinding Machine from RaymerBead Mill manufacturer, supplier, and exporter in Mumbai, India

Paints Industry: Raw materials & unit operations & Equipment

Paints is a main part of coatings, paints composed of five components which are; resin (binder), solvent, filler, pigments, and additives From the point of view of chemical engineering; paintsContribute to changjiangsx/ development by creating an account on / working of ball mill in paint ma nufacturing company

Ball Mill Principle, Construction, Working, and More Soln

A pharmaceutical ball mill is a type of grinder used to grind and blend materials while manufacturing various dosage forms The size reduction is done by impact as the balls drop from near the top of the shell Ball mills are used primarily for singlestage fine grinding, regrinding, and as the second stage in twostage grinding circuitsBall Mill Working Principle The ability to finely grind materials and control the grinding process makes ball mills crucial equipment in cement manufacturing Mining and Ore Processing: Paint and Coatings Industry: Ball mills are used in the paint and coatings industry for the dispersion of pigments and additives into a liquid mediumBall Mill Grinding Machines: Working Principle, Types, Parts

/ working of ball mill in paint nufacturing company

Contribute to sili2023/ development by creating an account on Energysaving ball mill, double row selfaligning spherical roller bearings, the running resistance of small, energysaving effect is remarkable The cylindrical part, the discharge end of the original cylinder increase over a conical cylinder, both to increase the effective volume of the mill, and also allows more rational allocation barrelAdvantages And Disadvantages of Ball Mill TON Heavy

ball mill paint manufacturing

Jul 12, 2018 High quality customized paint ball mill for sale with competitive price ISO 9001 and high capacity from Henan Hongji OEM Hongji Ball Mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, Sarbjeet Singh and Pardeep Singh, “Estimation and evaluation of reliability, availability of ball mill in paint manufacturing unit,” International Journal of Scientific and Technical Advancements, Volume 2, Issue 4, pp 245248, 2016 International Journal of Scientific and Technical Advancements ISSN: 24541532Estimation and Evaluation of Reliability, Availability of Ball Mill in

Estimation and Evaluation of Reliability, Availability of Ball Mill

Sarbjeet Singh and Pardeep Singh, “Estimation and evaluation of reliability, availability of ball mill in paint manufacturing unit,” International Journal of Scientific and Technical Advancements, Volume 2, Issue 4, pp 245248, 2016 International Journal of Scientific and Technical Advancements ISSN: 24541532China Paint Mill manufacturers Select 2023 high quality Paint Mill products in best price from certified Chinese Mill Equipment, Roller Mill suppliers, wholesalers and factory on MadeinChinaPaint Mill MadeinChina

Effects of Ball Size on the Grinding Behavior of Talc Using a

Highenergy ball milling at 2000 rpm produces ultrafine talc particles with a surface area of 4191 m2/g and an estimated spherical diameter of 51 nm Increasing the ball size from 01 mm to 2 mmExtending the Operational Life of Your Ball Mill: Cleaning and Maintenance Guide Regular cleaning of ball mills, tailored to the processed material and equipment design, can significantly enhance their operational efficiency and lifespan Chemical cleaning agents offer superior cleaning, minimizing labor, downtime, and risk of Ball Mill Cleaning & Maintenance Guide: Extending Operational Life

Ball Mill Principle, Application, Uses, Critical Speed, Diagram

The ball mill manufacturing industry in India has been growing at a steady pace, thanks to the Established in the year 1993, the company specializes in designing and manufacturing a wide range of ball mills Construction, and Working of Hammer Mill and Ball Mill Important Pharmaceutical Uses of Clove, CinnamonA ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation It consists of one or more rotating cylinders partially filled with grinding balls (made(PDF) Grinding in Ball Mills: Modeling and Process Control

Basket Mill manufacturer, supplier, and exporter in Mumbai, India

Working/ Operating Principle of Basket Mill Basket mills are very fastrunning mills in fixed design with extremely variable speed adjustment by static frequency converter for the discontinuous fine dispersing & fine grinding in the batch production system In a Basket mill, t he rotating motor drives the pins and dispersing disc to rotate 11 Ball Mill: In case of continuously operated ball mill, the ceramic balls are fed up to 1/3rd portion of its volume As the shell rotates, the balls are lifted up on the rising side of the shell and then they cascade down (or drop down on to the feed), from near the top of the shell In doing so, the solid particles in between the balls are ground and Production & Operations of Paint PPT SlideShare