define a ball mill how are possible to rotate in one

What Is a Ball Mill? Blog Posts OneMonroe

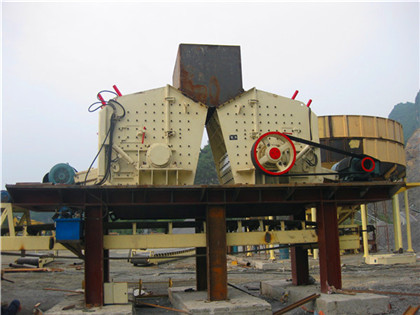

Overview of Ball Mills As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove The ball mill process is a mechanicalchemical process that uses mechanical force to induce the chemical and structural change of certain materials (Amusat, Kebede, Dube, Ball Mill an overview ScienceDirect Topics

Ball Milling an overview ScienceDirect Topics

Ball milling: The main principle of mechanical milling can be described as the exploitation of high energy grinding to reduce the particle size In general, the high energy ball milling Abstract and Figures The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial (PDF) Grinding in Ball Mills: Modeling and Process Control

Converting a ball mill from overflow to grate discharge TON

One way of fully utilising the capacity of a ball mill is to convert it from an overflow to a grate discharge This can allow an operation to increase plant throughput or The meaning of BALL MILL is a pulverizing machine consisting of a rotating drum which contains pebbles or metal balls as the grinding implementsBall mill Definition & Meaning MerriamWebster

Effects of rotational direction and rotationtorevolution

The rotational direction of a pot in a planetary ball mill and its speed ratio against revolution of a disk were studied in terms of their effects on the specific impact Ball Mill The ball mill’s basic concept dates back to prehistoric times when it was used to grind flint for pottery A pharmaceutical ball mill is a type of grinder that is used to grind and combine materials Ball Mill Pharmacy Gyan Principle Construction

The working principle of ball mill Meetyou Carbide

22 May, 2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automaticallyCERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volumeBall Mills 911 Metallurgist

Construction and Working of Ball Mill Solution Parmacy

Working of Ball Mill The material to be ground is kept in a hollow cylinder The material is placed up to 60% of the volume A fixed number of balls is placed in the cylinder and then the cylinder is closed The mill is allowed to rotate Speed of rotation is an important point of considerationThe operating principle of the ball mill Feb 08, 2017The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding mediadefine a ball mill how are possible to rotate in one mint

Ball Mill Working Principle, Construction, Application and

The length of the mill is approximately equal to its diameter Principle of Ball Mill : Ball Mill Diagram • The balls occupy about 30 to 50 percent of the volume of the mill The diameter of ball used is/lies in between 12 mm and 125 mm The optimum diameter is approximately proportional to the square root of the size of the feedAbstract This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into fine powder and capable to work efficiently The cylindricalDesign and Fabrication of Mini Ball Mill (edited) ResearchGate

Ballmilling ResearchGate

Ball mill is crucial to numerous industries as an equipment for producing extremely crushed materials, eg cement, refractory materials, fertilizers, glass ceramic, ore dressing of ferrous asBall Mill Sole Plate This crown should be between 002″ and 003″, per foot of length of sole plate For example, if the sole plate is about 8′ long, the crown should be between 016″ and 024″ Ball Mill Sole Plate After all shimming is completed, the sole plate and bases should be grouted in positionBall Mill Maintenance & Installation Procedure 911 Metallurgist

Ball Mill an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightOnce the presentation is open, navigate to the slide you want to rotate Click on the slide to select it, and then click on the "Design" tab located in the top menu bar From the design tab, select the "Slide Size" icon, which is located to the right of the "Themes" icon A dropdown menu will appear, and from the menu, select the "Custom How to Rotate a Slide in PowerPoint Zebra BI

How to Rotate in Unity (complete beginner’s guide)

Which means that, using vectors, it’s possible to rotate the position of one object around another in Unity, without actually rotating the object itself For example Let’s say that I want to orbit one object, a Position the wood pieces so that the base sits at a height of 4” (1016 cm) You can secure the wood pieces in place with some How to Make a Ball Mill: 12 Steps (with Pictures)

CSS rotate property W3Schools

The rotate property defines a value for how much an element is rotated clockwise around zaxis To rotate an element around xaxis or yaxis or in other ways, this must be defined Values for rotate property can be given as one angle, axis name + angle, or three values + angle If an angle is given, the element is rotated clockwise around zaxisA Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formulaBall Mill Critical Speed 911 Metallurgist

define a ball mill how are possible to rotate in one

[randpic]define a ball mill how are possible to rotate in one Top We have define a ball mill how are possible to rotate in one ,Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away asA 3axis clone of a Bridgeportstyle vertical milling machine Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpieceThis may be done by varying directions on one or several axes, cutter head speed, and pressure Milling covers a wide variety of different operations and machines, Milling (machining)

Ultimate Guide: How to Rotate in Photoshop Envato Tuts+

But this was just one answer to the question of how to rotate an image in Photoshop! If you have more images in your file, and you use the previous method of rotation, they will all be rotated together If you want to rotate one layer only, you should use a different method First, select the layer that you want to rotateRotation on local axes can always be achieved by pressing R and then twice the key for the axis: R, Z, Z to rotate on local axis Pressing Z once is global Z axis, pressing Z again is local Z axis, pressing Z a third time gets you back to global rotation Or to generally rotate on local axes with pressing the key only once, you can change theHow to rotate an object around another object's local axis?

What’s the Difference Between SAG Mill and Ball Mill

The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mm The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s