solid liquid separation centrifugal separator

Use of centrifuge how separation works Alfa Laval

A clarifier is a centrifugal separator for solid liquid separation, that removes solids such as particles, sediments, oil, natural organic matter and colour from process liquids In doing so, the process liquid becomes clearThis Project Standards and Specifications covers minimum requirements for the process design (including criteria for type selection) of solidliquid separators used in the PROCESS DESIGN OF SOLIDLIQUID SEPARATORS

SolidLiquid Separation: A Guide to Centrifuge Selection

Solidliquid separation through centrifugation is often a crucial step to obtain the desired product after precipitation or crystallization There are two types of centrifugation (also A purifier is a centrifugal separator for liquid liquid solid separation, that separates two liquids of different densities, and a solids, such as water, oil, and fines, from each other Using a purifier the light liquid Types of separation duties Alfa Laval

Centrifugal Separator Centrifuges and Separators

GEA separators are designed for liquidbased applications Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different There are various methods to separate liquid phases and solids from liquids Two most common technologies are centrifugal separation and filtration Decanters and disc stack separators also referred to as Different separation technologies Alfa Laval

Separator designs for solids handling Alfa Laval

It separates solids and one or two liquid phases from one another using extremely high centrifugal forces The centripetal force generated by the rotating bowl pushes solids against the periphery of the bowl, while the Decanter centrifuges or solid bowl centrifuges (SBCs) are widely used in separation applications ranging from solidliquid separation to the classification of Modelling solidliquid separation and particle size

LIQUIDSOLID SEPARATION

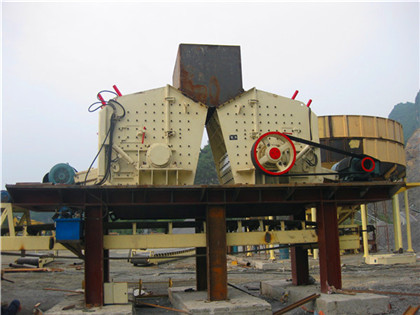

Liquidsolid separation involves the separation of two phases, solid and liquid, from a suspension It is used in many processes for the: 1 recovery of valuable solid component (the liquid being discarded); 2 liquid recovery (the solids being discarded); 3 recovery of both solid and liquid; or 4 recovery of neither phase (eg, when a liquid is Centrifugal separators can be used for the mechanical separation of water from vegetable oils or biodiesel and the rapid separation of biodiesel and glycerol posttransesterification process Fig 612A shows a centrifugal separator platform fabricated by Crown Machinery (Liaoyang, China) [33]The separator consists of a main frame and components, that is, Centrifugal Separator an overview ScienceDirect Topics

Centrifugal Separators: Working Principle And Design

A centrifuge is one piece of separation technology that allows for high speed separation of immiscible (think “nonmixable”) liquids and particles Centrifuges are built around a rotating chamber (often called a “bowl” or “rotor”) The rotor’s acceleration generates a centrifugal force that is, essentially, a sort of artificialA Clarifier is a centrifugal separator designed for solidliquid separationThe objective of clarification is solids separation from a liquid phase In a clarifier centrifuge, the gravity disc is replaced by a sealing ring (clarifier disc), closing the passage of water to the water chamber in the centrifuge bowl topThis closure of the heavy phase pathway essentially Disc Stack Centrifuges Separator Spares & Equipment

Scaleup of Centrifugal SolidLiquid Separation

Scaleup of Centrifugal SolidLiquid Separation gets thinner, and that the thickness becomes one where it is difficult to scrape the cake with an upright centrifugal separator Thus, we can see that any filtering using an upright centrifugal separator a criterion of αav ≤ 1010 m/kg is preferable for αav 4A purifier is a centrifugal separator for liquid liquid solid separation, that separates two liquids of different densities, and a solids, such as water, oil, and fines, from each other Using a purifier the light liquid phase is typically Types of separation duties Alfa Laval

Centrifugal separator, the new technical solution, application in

For the separation of mixtures solid–liquid, where the difference in density is great, this separation technology is completely acceptable The realized acceleration is relatively small (most often around 60 g for Knelson concentrators, ie around 600 g for Falcon concentrators) the concentration quality is 3–70% for the input Centrifugal Separator GEA separators are designed for liquidbased applications Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, ie they can be used for liquidliquid separation, for liquidliquidsolid separation or for liquidsolid separationCentrifugal Separator Centrifuges and Separators

Centrifugal Solids Separator Solid Liquid Separator Rosedale

8008215373 Filter Filtration Systems Application Based Liquid, Gas, and Water Filter HousingsSOLID/LIQUID SEPARATION AND SOLUTE CONCENTRATION Hyperfiltration Ultrafiltration High Speed Centrifugation Microfiltration Conventional Filtration E v a p o r a t i o n 01 10 10 Self cleaning separator Nozzle bowl separator Centrifugal decanter SOLIDS CONTENT Title: No Slide Title Author:SOLID LIQUID SEPARATION: CENTRIFUGATION MIT

CENTRIFUGAL SEPARATORS FOR INDUSTRIAL APPLICATIONS

We provide solutions to any technological solidliquid and solidliquidliquid separation problem, through centrifugal separators which are placed on a large variety of application fields with a wide range of flow rates The centrifugal force effective, reliable and innovativeIt can separate suspensions with a solid concentration of less than 3% The technical parameter range of disc centrifuge is relatively large, and the diameter of the drum is generally 150 ~ 1200 mm The disc centrifugal Disc Centrifuge SolidLiquid Separation Disc Stack

Design of Centrifugal Separator for Dehydration IJREAM

Dehydration is the process of separation of liquid from solid matter In Centrifugal Separator, the mixture of solid and liquid waste is poured in a vessel rotating at high speed Due to this, the centrifugal force acts on the mixture As liquid has less density than solid, it is thrown outside the vesselOwing to the high centrifugal force, the solidliquid separation process in the SBC is significantly faster than that under the gravitational force The SBC, therefore, is typically regarded as a type of highefficiency solidliquid separation equipment An oftenoverlooked function of SBCs is particle classificationsModelling solidliquid separation and particle size classification

Centrifugal Separator Multotec

Our centrifugal separators: efficiently separate solids from liquids, for particles of all sizes recover valuable minerals from slurries help plants reduce their waste, work towards ZLD reduce thermal drying times and costs improve the quality of discharged contents reduce their environmental footprintSolid discharge FRAME 9ROTATING BOWL "AIIt SPACE LIGHT LIQUID SOLIDS HEAVY LIQUID q~BRAKE LIQUID i INLET (d) (e) Figure 1113 Filtering centrifuges (a) Top suspended batch centrifugal filter; the cake is scraped off the screen intermittently at lower rotation speeds of 50 rpm or so, cake thicknesses of 26 in, cycle SolidLiquid Separation ScienceDirect

A Resolved Simulation Approach to Investigate the Separation

The separation of finely dispersed particles from liquids is a basic operation in mechanical process engineering On an industrial scale, continuously operating decanter centrifuges are often used, whose separation principle is based on the density difference between the solid and the liquid phase due to high gforces acting on both 1 Introduction to solidliquid separation L Svarovsky Pages 1 29 Publisher Summary This chapter discusses separation technology as a dominant feature in the chemical process Filter aids are rigid, porous, and highly permeable powders are added to feed suspensions to extend the applicability of surface filtration, in this technologySolidLiquid Separation ScienceDirect

CENTRIFUGAL SEPARATION Factory & Manufactor Huading Separator

Centrifugal Separation Technology is the most widely used method for separating fluids with different densities It is also used in separating solids from liquids or solids from gasses The need to separate different liquid phases and solids from each other is part of practically every industrial process Huading Separator has more than half a•In this module the solidliquid separation is based on movement of solid particles or liquid drops through fluid In this study the fluid is liquid •The solid particles present will be eliminated from the liquid stream •In the separation the desired product may be solid or liquid •Gravity settling is the process where solidliquidMODULE 3: SOLID LIQUID SEPARATION Birla Institute of