Measuring Tool Crusher Jaw Opening

How to measure the theoretical output of a jaw crusher LinkedIn

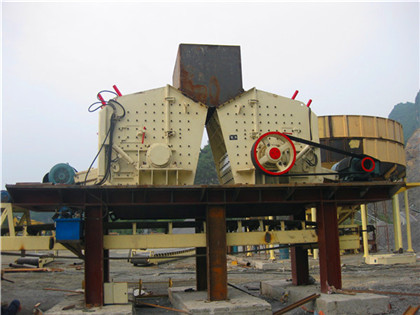

jaw crusher The theoretical output of a jaw crusher can be calculated using the formula: Output = (Width of Jaw Opening) x (Gape) x (Rate of Reduction) The utility model belongs to width measurement technical field, more particularly, to a kind of jaw crusher feed opening adjustment width measuring scale, it is characterized by CNU Jaw crusher feed opening adjustment width

Jaw Crusher an overview ScienceDirect Topics

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time This is dependent on the area of the discharge The utility model is simple and effective, and brings much convenience; the jaw crusher is safe and reliable, can measure in jaw crushing movement, can measure the minimum CNU Jaw crusher ore discharge opening and jaw plate

Jaw Crusher ScienceDirect

A Blake jaw crusher had the following dimensions: Gape = 160 cm, open set = 244 cm, close set = 50 cm The width of the hopper was 15 times the gape The For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate Jaw Crusher Explained saVRee

McLanahan How To Size A Jaw Crusher

A Jaw Crusher is sized so that the maximum feed size is 80% of the gape and width openings The gape is the measurement between the two jaw dies, while the The design parameters of the crusher include the size of the top opening, the set, the volume of the crushing chamber, and the type of jaw surface, which may be smooth or corrugated The equipment operational parameters include the frequency and amplitude of the movable jaw stroke, the feed rate, the closed side setting (CSS) of the Minerals Free FullText DEM Simulation of LaboratoryScale Jaw

Jaw Crusher Working Principle PDF Economic Sectors Nature

8/19 The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw The crusher discharge opening governs the size of finished material produced by the crusher Measuring Discharge Opening: 1 Measure distance at bottom of jaws at theAims: To investigate the effectiveness of a novel jawopeningforce measuring device as a screening tool to aid in the diagnosis of temporomandibular disorders (TMD) Methods: Symptomatic TMD patients (n = 58) and control TMDfree participants (n = 56) were screened by an oral medicine specialist according to the Diagnostic Criteria for TMD (DCCan the Measurement of JawOpening Forces Assist in the

measuring tool crusher jaw opening

T04:10:12+00:00 Jaw Crushers McLanahan The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first After measuring the crusher’s oss, the css should be calculated to define what the opening of the crusher is to be and The Big Bite jaw crusher (KueKen Div, Process Technology Inc) is a Blake doubletoggle type in which the fulcrum pinion is positioned well over the center ofthe grinding chamber [Anon, Quarry Management, 18(1), 257 (1991)] This increases the throw at the top of the jaw opening, allowing it to better crush large rocksJaw Crushers Size Reduction Beyond Discovery

Jaw crushr operate manual: how to install, repair and examine it

Installation points of the movable jaw Assemble the movable jaw parts in advance After assembling the movable jaw, movable jaw shaft, movable jaw plate, toggle pad, etc on the ground, use a crane or crane to hoist the assembled parts together on the crusher In the rack For sliding bearings, it is necessary to grind and match between theThis is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing That’s what you’ll find here!Cone crusher basics in 4 minutes — SRP

Measuring The Crusher Setting PDF Business Scribd

Issue 44 September 2011 TONS NEWSLETTER FOR CONSTRUCTION CUSTOMERS Jaw Crusher Measuring the crusher setting In order to maximize your crushing plants production performance (throughput), it is essential that all its equipment is tuned and adjusted properly The opening of the primary crusher, for example, will Jaw Plant Optional RunOn or Leveling Jacks The Cedarapids CRJ3255 jaw plant combines the popular JW55 jaw crusher with the high stroke 52”x20’ vibrating grizzly feeder making this plant a high production portable crushing machine This quarry duty JW55 crusher, with its large 32”x55” opening, long jaws, and aggressive stroke,Cedarapids Portable Plants CRJ3255 Jaw Plant

TON ® C Series™ jaw parts

C Series™ jaw crusher basic concepts 4 How to operate a C Series™ jaw crusher 6 C Series™ jaw crusher wear parts 8 One or twopiece jaws 10 MX jaws 11 When to change jaw dies 12 How to change jaw dies 13 Maintenance tools 14 Complementary products 15 ® C Series™ jaw crusher ContentsFebruary 2018, Volume 5, Issue 2 JETIR (ISSN23495162) JETIR Journal of Emerging Technologies and Innovative Research (JETIR) jetir 503 DESIGN OPTIMIZATION OF SWING JAW PLATE OFFebruary 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162) DESIGN

how to measure jaw crusher

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimensionThey are typically controlled by a hydraulic system that can be adjusted to provide the desired jaw opening size To adjust the hydraulic toggle cylinders, you will need to locate the controlHow to adjust a toggle spring on a jaw crusher? LinkedIn

How to select a crusher to crush different minerals? LinkedIn

jaw crusher and impact crushers from TON Mohs hardness scale is a useful tool to measure the hardness of minerals, and it ranges from 1 (softest) to 10 (hardest) C Series jaw crushers are easily installed into either new plants or to replace older jaw crushers to extend plant lifetime and boost production The modular concept makes the C Series jaw crushers easy to install The crusher can be installed as one compact module that includes all the necessary auxiliaries around the crusher itselfTON Crushing and screening solutions AggNet

measuring tool crusher jaw opening

kolkata measuring tool crusher jaw opening The 911MPEJAC23 is a Small Jaw Crusher of X 3 quot manufactured to easily crush any rock from 2 quot 50mm down to a D50 of 700 micron 28 Mesh which also correspond to a crushed discharge P80 size of 80 passing 1400 microns or 14 mesh The discharge opening closedsidesetting of this 55 mm X 75 mm For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 457/085 = 536 cm and for a shape factor of 17, the width should be = 457 × 17 = 78 cmmeasuring pitch line gap in a s crusher

ATOS TheraBite RangeofMotion ROM Scales CranioRehab

Include Instruction Card The TheraBite RangeofMotion (ROM) are disposable paper measuring scales, specifically designed to allow patients and providers to measure the opening, movement and function of the mouth and jaw With simple use and accurate tracking, patients are motivated and clinicians feel more assured in progressThe maximum feed size is approximately 8 0% of the feed opening The open side setting is measured when the crusher is at rest The setting is measured either top to top, or bottom to top, depending on the tooth profile of the jaw dies The closed side setting can be calculated by deducting the stroke from the OSSCrusher Close Side Settings 911 Metallurgist

JawOpening Force as a Useful Index for Dysphagia: A Cross

Abstract Introduction: Jawopening force (JOF) can be a potential screening tool for dysphagia However, confounding variables such as comorbidities or physical and oral functions that are associated with the physiology of swallowing have not previously been examined Adjusting for these variables could reveal the relationship