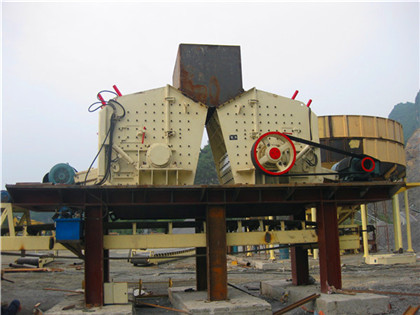

Easily Operated Impact Crushing Machine

Portable Impact Crushers MEKA Concrete Plants

MEKA Portable Impact Crushing plants are wheelmounted rock crushing machines, engineered to operate as a complete standalone closedcircuit unit with two or three products capabilityFields of application and design characteristics thyssenkrupp impact crushers are suitable for both coarse and fine crushing They crush mediumhard to hard material mainly Industrial Solutions Impact crushers ThyssenKrupp

Impact Crusher an overview ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force MEKA Portable Primary Impact crushers combine the rugged reliability of our impact crushers with the high stroke grizzly feeders for a high production portable primary crushing machine DESCRIPTIONS Portable Primary Impact Crushers MEKA Concrete Plants

Impact Crushers Parker Plant

The models of HD impact crushers are featured within the Parker tracked units, along with the standard configurations of static and mobile/transportable options for modular plant Find your impact crusher easily amongst the 366 products from the leading brands (MEKA, , Yuhang Heavy Industries,) on DirectIndustry, the industry specialist for your Impact crusher, Impact crushing and screening plant All

How does an impact crusher work? RUBBLE MASTER

RUBBLE MASTER impact crushers use a simple design to change the crusher setup easily, quickly and safely within minutes The unique proprietary crushing chamber design allows operators with limited machinemade sand processing and other fields PFW European version impact crusher is a crushing machine that uses impact energy to crush materials This series of Crusher, Crushing plant All industrial manufacturers

The Rise of Mobile Impact Crushers Heavy Equipment

The mobile impact crushing plant is a versatile, trackmounted machine that can be used for aggregate production or the recycling of C&D material, asphalt and concrete In this article, we focus K Bhaskar and M Yohan, "Design and fabrication of solar powered can crushing machine," International Journal of Technical Innovation in Modern Engineering and Science, Vol 3, No 10, pp 98102(PDF) Design and Development of Can Crushing Machine

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG3 mobile Capacity: 50 t/h 240 t/h Motor power: 159 kW Opening height: 1,065 mm Ecofriendly performance moving to a new stage The operating weight of the BR380JG3 ranges from 33,500 to 35,310 kg, with a Crushing equipment is used to reduce the size of hard waste materials so that they can be easily recycled They can also be used to distinguish between pieces of various compositions Screening is typically used to separate coarse materials at the end of the process It's the last step in the process of separating differentsized materialsCrushing, Screening, and Mineral Processing Equipment: AMA

Design and Construction of Rock Crushing Machine from Locally

The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals for indigenous use The research work was tailored mainly on the design and production of locally fabricated rock crushing machine for indigenous useYou can choose the most suitable one to meet your demands If you cannot decide which type to buy, we will provide you with the most professional suggestion PF1007impactcrusher Model: PF1007 Specifications (mm): 1000*700 Diameter of feeding inlet (mm): 400*730 Max feeding Aggregate Size (mm): 300 Capacity (t/h): 3070Impact Crusher For Sale With 30800 t/h Processing Capacity

Impact Crushers Parker Plant

Available in three sizes, the well proven original Parker ‘Kubitizer’ Impact breaker produces material with outputs ranging from 40200 tonnes per hour and is ideal for working in a composite crushing arrangement with Parker primary crushing plants, screens and conveyors Feed material is broken along natural lines of weakness (the grainThe Can crushing machine is designed to crush aluminum waste cans by 80% reduction in volume It is used primarily to ease transportation of aluminum waste for recycling purposes The machine isDesign and Fabrication of Pneumatic Can Crushing Machine

Physical Bauxite Processing: Crushing and Grinding of Bauxite

The highspeed impact machines inherently have a high size reductionratio capability This means that the highspeed impact crushers can reach the final product size in less crushing stages than a compression crushing circuit, or a lowspeed sizer circuit, given that all the feed parameters are the same, and when those feed parameters Our mobile VSI crushing plant aims to deal with soft and hard ores to make them into high quality sand and aggregate products production and great versatility, Shunzhi mobile VSI crushing plant is able to accomplish a large amount of products quickly Model SZYY250 ~ SZYY800, SZCLY300 ~ SZCLY800 Crusher ModelMobile Crushing Plant For Sale Shunzhi Mining Machinery

Crusher an overview ScienceDirect Topics

Mechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer Conclusion Mobile rock crushers are essential tools for the construction and mining industries They offer a range of advantages, including increased mobility, reduced operating costs, and improved Benefits of Mobile Rock Crushers in the Construction

10 Popular Crusher Manufacturers & Suppliers in India

1 Ecoman Established in 1982, Ecoman is one of the leading crusher manufacturers in the country The company has a huge list of satisfied customers after all these years of working 2 Kanteen India An impact crushing machine provided with easily repairable strikers fixedly arranged along the circumference of a rotor at regular angular intervals so as to extend radially of the rotor so that the frequency of replacing the heavy striker with a new one is reduced and the operating cost of the impact crushing machine is reducedImpact crushing machine Kabushiki Kaisha Kobe Seiko Sho

Mobile Crusher in UAE on Yellow Pages, UAE

Wheelmounted semimobile crushing units combine both primary and secondary crushing operations Some popular locations to get in touch with mobile crushers in the UAE are Sheikh Zayed road, Hamdan Street, Al Quoz Industrial area, Al Aweer, Ras Al Khor, Jumeirah, Airport Road, Deira, Musaffah Industrial area, ICAD Abu Dhabi, Reem Island Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can be classified into to two basic types, crushers and grinders Industrial crushers are the first level of size reducer; further granularizationHow it Works: Crushers, Grinding Mills and Pulverizers

Understanding comminution: Compression versus impact crushing

A steady compression force applied by closing the product between the mantle (or jaw) dies and the crushing chamber’s wall Compression crushers such as cones and jaw crushers normally have lower reduction ratios than impact crushers like a horizontal or vertical impact crusher However, they offer much greater control over the output asCone crusher price: $26,000 ~ $45,000 Impact crusher price: $20,000 ~ $140,000 Mobile type: Compared with the stationary type, the mobile crusher plant price is a little higher The mobile crushing plant price is at least $550,000, but not more than $2,500,000 If your budget is enough, consider the mobile oneCrushing Plant in The Philippines AIMIX OneStop Crush Solution

(PDF) DEVELOPMENT OF A PORTABLE BONE CRUSHING AND GRINDING MACHINE FOR

A portable bone crushing/grinding machine for both small and medium scale industrial use was designed, constructed and tested In the designing and material selection, consideration was given toTo solve this issue already exist highly operated machines but they are too costlyso, Shear Strength and Impact Strength Machines Available for Recycling are costlier and setup is also “Designing of a Portable Bottle Crushing Machine” IJSRD International Journal for Scientific Research & DevelopmentVol 4, Issue 07,IOP Conference Series: Materials Science and Engineering PAPER

McLanahan What Type of Crusher Is Best for Primary Crushing?

Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke, coal and more Using a combination of impact, shear and attrition reduction methods,